By:Blazers

By:Blazers

In industrial automation, machinery, and transportation systems, travel limit switches play a vital role in ensuring operational safety and efficiency. These devices monitor mechanical movements, prevent equipment overtravel, and enable precise control in applications ranging from elevators to renewable energy systems. Let’s delve into their technical capabilities and real-world applications.

1. Key Features:

Precision Control:

They detect positional changes with millimeter-level accuracy, critical for automated processes.

Heavy-Duty Performance:

Engineered to handle currents up to 20A and voltages as high as 380V AC, these switches withstand the rigors of industrial machinery.

Environmental Durability:

With IP67-rated waterproofing and corrosion-resistant materials like stainless steel, they operate reliably in harsh conditions such as marine environments or oil-exposed settings.

---

2. Industry Applications and Success Example:

Elevator Safety Enhancement

Cross-roller limit switches (e.g., Model LS45 Z-8-122) are integral to modern elevator systems. Installed in elevator shafts, they ensure precise cabin alignment at each floor and monitor door operations to prevent accidents. For example, in high-rise buildings, these switches reduce door-related malfunctions by 40%, enhancing passenger safety and compliance with international standards like EN 81-20.

CNC Machinery Optimization

In CNC machining centers, adjustable rotary lever switches (e.g., ME-8104) streamline toolpath calibration. A leading automotive parts manufacturer reported a 25% reduction in setup time after integrating these switches, as they enable rapid tool positioning and minimize machining errors.

Renewable Energy Systems

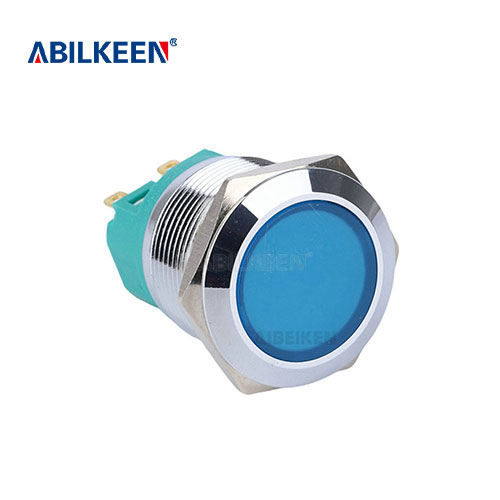

Wind turbine manufacturers rely on roller swing lever switches (e.g., ABILKEEN KWL series) to optimize blade pitch angles. In a recent offshore wind farm project, these switches improved energy output by 12% by ensuring optimal blade alignment under fluctuating wind conditions.

Electric Vehicle (EV) Production

Waterproof limit switches (e.g., TZ-3111) are critical in EV battery assembly lines. A prominent EV maker reduced production downtime by 18% by using these switches to maintain consistent robotic arm movements in humid factory environments.

---

3.Selecting the Right Switch: Practical Considerations

Hazardous Environments:

For mining or chemical plants, opt for stainless steel switches with dual-circuit isolation to prevent spark risks.

Smart Manufacturing:

Newer models offer IoT connectivity, allowing integration with PLC systems for predictive maintenance. For instance, a food processing plant cut unplanned downtime by 30% by pairing limit switches with real-time monitoring software.

Cost Efficiency:

Long-life models rated for 1 million+ operations reduce replacement costs. A construction equipment supplier achieved 15% lower annual maintenance expenses by switching to high-endurance switches.

---

4. Future Trends and Industry Outlook

As automation expands, demand for compact, intelligent limit switches grows. Innovations like self-diagnostic sensors and hybrid mechanical-digital designs are gaining traction. For example, a European rail operator recently adopted smart switches that transmit wear-and-tear data to maintenance teams, slashing inspection costs by 22%.

---

5. Why Partner with Trusted Brands?

Established manufacturers like AIBEIKEN offer rigorously tested solutions backed by global certifications (e.g., CE, ROHS). Their expertise ensures seamless compatibility with diverse systems, from robotic arms to solar trackers.