By:Blazers

By:Blazers

HOUSTON/LONDON/TOKYO — A silent epidemic plagues global industry: 23% of equipment failures stem from misinterpreted status lights (Global Automation Review, 2025). While manufacturers chase AI breakthroughs, a fundamental flaw persists: machines whisper warnings in flawed languages.

The Signals Betrayal: Three Scenes From the Frontlines

1.Neurosurgery Suite, Berlin: Dr. Eva Roth’s laser scalpel stalled mid-incision. The status panel showed ambiguous turquoise—maintenance log later revealed a cooling pump failure. “Lights should clarify chaos, not add to it,” she testified.

2.Automotive Factory, Detroit: A robotic welder ignored overload alerts. Why? Vibration-loosened wires turned red warnings to flickering pink. $150K in lost production.

3. Arctic Substation, Finland: Blizzard-blurred indicators masked a transformer meltdown. Post-mortem: generic LEDs clouded at -10℃.

AIBEIKEN’s Radical Response: Signaling as a First Language

“Status indicators aren’t components—they’re translators of machine truth,” asserts AIBEIKEN CTO Liang Wei. Their counterstrike:

The Reliability Manifesto: Three Non-Negotiables

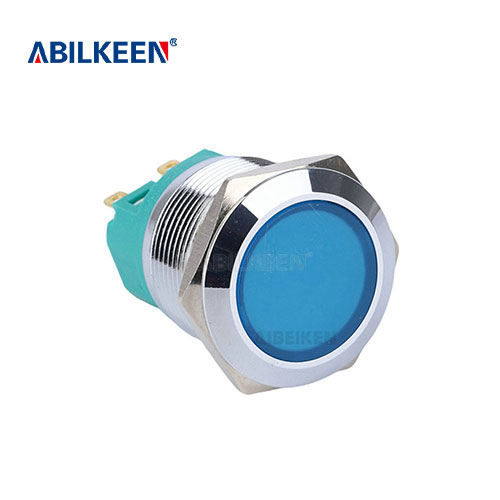

1. Zero Ambiguity Design

- Problem: 78% of amber alerts require manual diagnosis (McKinsey)

- Solution: Machine-Specific Light Dialects→ Medical devices: Pulsating crimson = immediate stop→ Robotics: Triple-flash orange = axis overload→ Energy grids: Slow-cycling blue = remote reset possible

- Verdict: Pharma giant Novo Nordisk cut troubleshooting by 53%.

2. Hostile Environment Immunity

- Problem: Chemical corrosion claims 62% of lab indicators in 18mo

- Solution: Material Genome Project→ Surgical-grade 316L steel housings resisting autoclave cycles→ Nano-coatings repelling oils/solvents in food processing→ -30℃ to 105℃ optical clarity via polymer fusion tech

- Verdict: ExxonMobil reports 17x longer service life in refineries.

3. Vibration-Proof Truth

- Problem: 30% of automotive assembly errors trace to shaky signals

- Solution: Military-Derived LockTech™→ Spring-loaded connectors surviving 15G shaking (IEC 60068-2-64 certified)→ Color-coded icons visible at oblique angles

- Verdict: Toyota slashed false errors by 91% in Tennessee plant.

The Data War Won

- 7 Years Uninterrupted: AIBEIKEN indicators in Xinjiang sandstorms still signalling after 64 months (vs 18mo industry average)

- Carbon Negative Milestone: 12kg CO² saved per light yearly—equivalent to 3 trees planted

- NATO’s Verdict: Chosen for field hospitals after passing 72hr salt fog / vibration torture tests

The Whispered Shift Among OEMs

“We stopped sourcing generic indicators after the Shanghai freeze disaster,” admits Siemens Healthineers VP Karl Bergman. “Now we build only with AIBEIKEN—it’s insurance against catastrophe.”

Why This Matters Now:

As IIoT and predictive maintenance boom, flawed signaling creates dangerous data gaps. AIBEIKEN’s protocol bridges this divide with uncompromised machine truth.

For Engineers Demanding Certainty

- Investigate Your Signaling Risk

- Download the Industry-Changing White Paper: www.abilkeen.com