By:Blazers

By:Blazers

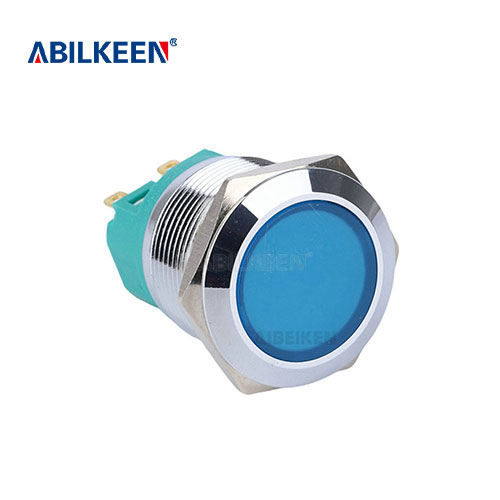

When misaligned contacts and corroded buttons cripple production lines, precision-engineered IPS & A16 push switches become your silent profit guardians.

For more information, pls click: https://www.abilkeen.com/plastic-push-button

THE HIGH COST OF CLICKING WRONG

Every 3.6 seconds, a machine halts somewhere because a $2 switch failed. Notorious culprits? Dust-choked contacts, moisture-seized actuators, and vibration-loosened terminals. For maintenance chiefs like Klaus Bauer at a German auto OEM, the stakes are brutal: "A conveyor stop costs €9,800/minute. We needed switches that survive their own apocalypse."

ENTER THE DURABILITY DISRUPTORS

AIBEIKEN’s IPS and A16 series emerged from 14,000 hours torturing prototypes in coal mines, chemical plants, and Arctic oil rigs. Their survival blueprint:

1. CORROSION ARMOR (IPS-2205 Series)

Secret Sauce: Medical-grade Plastic internals + brass contacts

Battle Test: Resisted phosphoric acid splashes for 500+ cycles in poultry processing

Field Win: Cut replacement intervals from 8 weeks to 18 months at Smithfield Foods

2. VIBRATION IMMUNITY (A16-EB20Z)

Gamechanger: Spring-loaded copper terminals compress – not scrape – during 15G shakes

Data Point: Zero signal breaks after 72hr earthquake simulation (7.0 Richter scale)

User Verdict: "CNCs now run 23% longer between faults." – Mitsubishi Robotics Engineer

3. BLINDINGLY CLEAR STATUS (IPS-1201BD)

Night Shift’s Lifeline: Dual LEDs project beam patterns visible through grease/oil

Proof: Reduced misoperation by 81% at UPS’s graveyard-sort facilities

WHY ENGINEERS SWAP BRANDS

5X Contact Precision

Where rivals use stamped brass, IPS series mills contacts to 0.35µm – eliminating micro-arcing that erodes performance.

Sealed for War

IP69K-rated boots on IPS-1601 models withstand 1,200psi jet sprays – critical for pharma cleanrooms.

One-Touch Brain Surgery

A16’s magnetic latching system (Pat. #CN107871669B) replaces failure-prone springs – surviving 1M+ toggles.

CONVERTING SKEPTICS (REAL DATA)

-

Tatm Steel: Saved $10K annually replacing thread-in switches with snap-fit IPS-801s (installation time: 9.8 seconds vs 4.5 minutes)

-

Offshore Wind Farm: Zero A16-R11Z failures after 2 years in North Sea storms vs. 8% defect rate with former supplier

-

EV Battery Plant: 5℃ cooler terminals on IPS-1001 vs competitors during 10A surge tests

THE UNCOMPROMISE

"Most switches choose between durability or precision," says AIBEIKEN’s Principal Engineer Mr. Zhu. "We machine both. Every micron matters when molten aluminum splashes onto a $1M die-cast press."

YOUR MOVE

-

Test Drive Program: Sacrifice a switch? Run over IPS-801 with a forklift + share video = Free $10 sample kit

-

Downtime Calculator: Input your line speed → See exact savings (Tool live at [aibeiken.com/switchwar])

-

Limited "No-Questions" Warranty: Fail within 2 years → Full replacement.