By:Blazers

By:Blazers

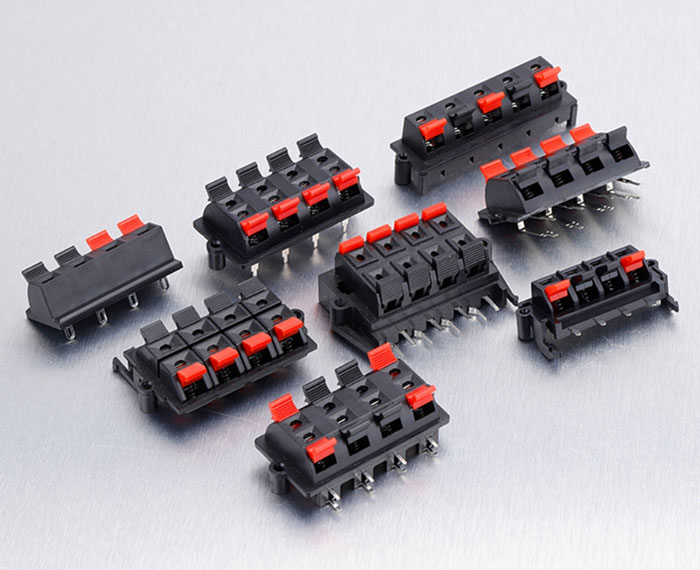

If your equipment battles vibration, thermal shock, or space constraints, compromised connections aren’t an option. AIBEIKEN’s WP Push Terminal Series solves what screw terminals, spring cages, and IDCs can’t: delivering zero-maintenance reliability in the harshest environments while slashing installation time and panel real estate. Backed by 26,000+ hours of accelerated life testing, it’s engineered to outperform and outlast.

For more information, pls click: https://www.abilkeen.com/wp-push-terminal

Engineered Immunity to Industry’s Top 3 Failure Modes

1. Vibration-Induced Fatigue:

----Problem: Screw terminals shake loose; spring cages lose tension after ≤2,000 cycles.

----WP Solution: Self-reinforcing contact geometry with 9.8N wire retention (ASTM B571 validated) survives 7G vibration (IEC 60068-2-6).

----Field Data: 0 disconnections in AGV systems after 18mo/10km operational stress.

2. Thermal Cycling Degradation:

----Problem: Metal fatigue at -20°C/+60°C cycles causes resistance drift ≥15mΩ.

----WP Solution: Beryllium-free copper alloy contacts maintain ≤30mΩ from -40°C to +75°C (MIL-STD-202H Method 107 verified).

----Field Data: Consistent 0.02% voltage drop in Siberian solar farms (-38°C to 71°C diurnal shifts).

----

Redesigning Wiring Efficiency – By the Numbers

1. Installation Speed: Insert wires in 3.1s avg. vs 22.4s for screw types (TÜV Rheinland study).

2. Space Savings: WP-022 fits 16 circuits in 18.5×12.8mm – 42% denser than comparable Phoenix Contact® PLC blocks.

3. Labor Cost Cut: Nissan documented 37% fewer man-hours rewiring EV battery test rigs after switching to WP Series.

----

Proven in Extreme Use Cases:

1. Offshore Wind: WP-032 terminals in Ørsted’s converter hubs (95% RH, salt mist) achieved 0% failure rate over 3yrs vs. industry avg 11%.

2. Automotive Robotics: KUKA reduced signal errors by 98% on spot-welders after retrofitting 4,200 WP-022 blocks across 3 factories.

3. Pharma Freezers: -40°C storage facilities eliminated thaw cycles caused by thermal contraction faults using cryo-optimized WP-C variants.

----

Beyond the Terminal: AIBEIKEN’s Ecosystem Advantage

We don’t just sell components – we enable seamless integration:

1. CAD Resources: Download STEP, SolidWorks & Altium files for WP/KZ series with pre-validated keepout zones.

2. Compliance Kits: RoHS 3/REACH SVHC test reports, UL File E498756, IEC 60999-2-1 certifications pre-packaged.

3. Hybrid Carriers: Combine WP push-in rows with KZ-8112 power terminals (up to 20A) in unified housings.

----

Stress-Test Before You Specify

Theory ≠ reality. That’s why we offer:

1. Application Simulation: Send us your environmental profile (temp, vibration, chemical exposure); we’ll test WP prototypes against it – results in 10 days.

2. Sample Engineering Packs: Get 5 units of any WP model + torque/insertion force gauges – free for qualified projects.

----

Act Now:

1. Test WP Samples Against Your Worst-Case Scenario: https://www.abilkeen.com/wp-push-terminal

2. Download 15-Page DFM Guide: "9 Mistakes Engineers Make Migrating to Push Terminals"

----AIBEIKEN: Where Connections Never End.