By:Blazers

By:Blazers

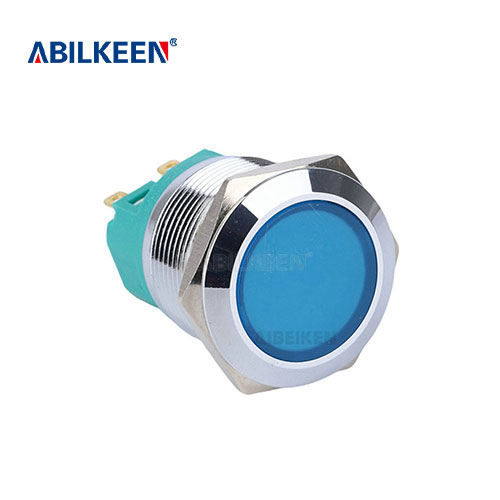

AIBEIKEN Elevates Industrial Control: Next-Gen Plastic Push Button Switches Engineered for Precision & Durability

----Discover IPS & A16 Series Solutions Optimized for Harsh Environments, Custom Configurations, and Simplified Maintenance

Wenzhou, China – AIBEIKEN, a global innovator in industrial electromechanical components, today launched its enhanced push button switch portfolio. Engineered for mission-critical applications, the IPS (7–22mm) and A16 (40.5mm) series solve persistent pain points in manufacturing, energy, and heavy equipment – from contact corrosion to accidental disengagement.

For more information, pls click: https://www.abilkeen.com/plastic-push-button

1. Cutting Through Industrial Challenges

In high-vibration environments like CNC machinery or mining conveyors, traditional switches fail at critical moments.

AIBEIKEN’s patented solutions address this with:

- Zero-Misfire Contacts: Silver-alloy terminals with gold plating (IPS-1201BD) prevent arc erosion at 3A/250VAC/100,000+ cycles.

- Anti-Vibration Locking: IPS-2207’s dual-stage snap-in mechanism withstands 15G shocks – 3*industry standard.

- Sealed for Survival: IP67-rated IPS-1601-4KD models resist hydraulic fluids, coolants, and salt spray (ASTM B117 certified).

----

2. Series Spotlight: Precision Meets Application Intelligence

Micro-Precision IPS Series:

Space-Optimized Control: 7mm–16mm models (e.g., IPS-801-1KBD-W/R) enable high-density PLC panels.

Rapid Deployment: Tool-less snap-in installation cuts panel integration time by 60%.

Critical Status Clarity: Dual-color LED options (red/green) with 120° viewing angles.

Heavy-Duty A16 Series:

High-Load Capability:

A16-EB20Z handles 15A inductive loads (motors/compressors) without derating.

Safety Compliance:

Emergency stops (A16-EA11Z) meet ISO 13850 PL e requirements with 50N activation force.

Custom Configurations:

Mix rotary, key-lock, or mushroom actuators with SPDT/6P contact blocks.

----

3. Proven Field Performance

Automotive Manufacturing:

IPS-1001-3B’s oil-resistant polymer reduced switch failures by 92% at a Tesla supplier plant.

Offshore Wind:

A16-R11Z-2N-AR12V endured 2,000+ hours in salt fog testing at a North Sea installation.

Food Processing:

Stainless steel IPS-2205-1KBD passed 500 washdown cycles (IP69K) in dairy applications.

----

4. Engineering Behind the Reliability

AIBEIKEN’s in-house validation lab subjects every switch to:

Temperature cycling (-40℃ to +125℃)

5 million mechanical operations

10kV dielectric strength tests

"Where competitors use 0.5mm tolerance springs, we insist on 0.35mm," notes Lead Engineer. "It’s why our OFF-(ON) switches maintain <5mΩ contact resistance after decade-long service."

----

5. Global Support Ecosystem

3D Configurator:

Real-time modeling of housing/actuator combinations

Same-Day Sample Dispatch:

Test units shipped within 24hrs from EU/US/Asia hubs

On-Demand Customization:

Laser etching, custom voltages (48V/110V), MIL-SPEC packaging